5 Simple Techniques For Custom Plastic Profiles

Wiki Article

Not known Incorrect Statements About Custom Plastic Extrusion Manufacturers

Table of ContentsCustom Plastic Profiles for Dummies5 Easy Facts About Plastic Extrusion Companies DescribedWhat Does Plastic Extrusion Profiles Mean?The Best Guide To Extruded Plastic ProfilesCustom Plastic Extrusion Manufacturers - Truths

We can likewise supply custom-made laminations and also would more than happy to send you samples upon request. We currently have seven lamination terminals that can manage lots of different kinds of personalized plastic extrusions. We provide custom-made packaging and are currently packaging an extruded profile product that is marketed to a "Huge Box" Business.Be it easy, intricate, hollow, coextruded, or printed, our group of professionals can personalize it for you. On top of that, our professionals understand that no two tasks are the same as well as we prepare to maintain it by doing this. This indicates that right here at Keller Products we can provide you any type of number of products for your design requires.

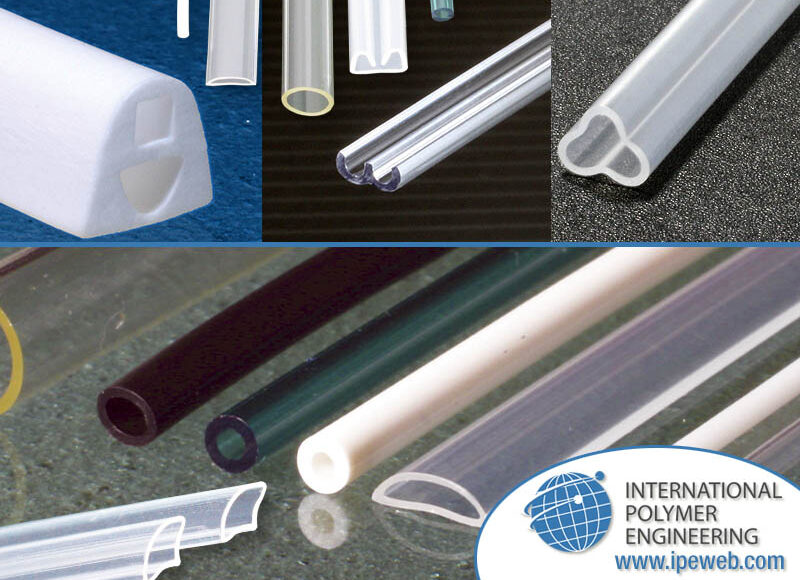

Customized extrusions are customized products that are produced forcibly raw products through a die or mold. This procedure is referred to as extrusion. Extrusion is utilized to produce objects of a taken care of cross-sectional profile, such as pipes, tubing, and also rods. The raw material, called the "extrudate", is very first softened by home heating.

The form of the die or mold figures out the final shape of the extrudate. Extrusion can be made use of to develop products from a selection of products, including steels, plastics, and also compounds. Typical applications for this process consist of vehicle parts, electrical conduit, and weatherstripping. It is made use of in a variety of industries, consisting of automotive, building, and also production.

The Buzz on Custom Plastic Extrusions

There are a number of business that deal in this sort of production. These firms can aid you to design the excellent product for your demands and afterwards produce it making use of the extrusion procedure. If you have a need for tailor-made items, personalized extrusion associated processing may be the excellent remedy. Prototyping your next crucial task can be as very easy as calling Alpha Custom-made Extrusions, Inc.In addition, Alpha Custom-made Extrusions, Inc. supplies a host of second capacities to complete your overall task. Call today!.

Include joints, seals, leading layers, numerous shades and other features

The Greatest Guide To Custom Plastic Extrusions

Our invoice of your purchase order starts the organizing process. What is the common lead time for a production order? The dynamics of personalized production usually result in quick modifications to tooling, manufacturing as well as manufacture routines.

How long does a custom color match take? It typically takes ten functioning days to get a color chip to you for authorization, as well as 10 added working days to generate the customized shade concentrate from the approved color chip.

What is the optimum possible width of an account? The extrudable profile is computed by determining its industrialized size.

Not known Details About Extruded Plastic Profiles

We've anonymous been doing it right given that 1962 and also are certain that your job will profit from our extensive experience in:. extrusion of plastics. https://hearthis.at/k3ll3rpl4st8/set/keller-plastics/.Flexible shapes are often coiled onto reels and also shipped to customers as reel supply. NCS additionally provides co-extruded materials of different durometers and different products that are co-extruded right into the very same component. Co-extrusions are made use of thoroughly in home window and also building and construction applications. If you have concerns about co-extrusions or any of our extruded plastic items, please connect to our group to find out extra (https://docs.google.com/forms/d/e/1FAIpQLScJVidX0jQkVSBU7f7d3Iy6JJt14iCoPgvz9DpJ3YBLxHQ3lw/viewform).

Extruded plastic forms are developed making use of a high-volume manufacturing procedure where raw plastic resin material is melted, then required through a die to create a continual account. To develop plastic extruded forms, the resin is placed right into the barrel of an extruder after that gradually thawed. Heat as well as stress is after that made use of to require the molten plastic into a die.

The Best Strategy To Use For Extrusion Of Plastics

With just a minor modification, extrusion molding can go from creating intricate shapes to plastic sheets. After plastic leaves the extruder, it remains warm and also can be more adjusted. This enables makers to change the shape of extruded plastic utilizing rollers, shoes, or dies to meet the certain demands of several applications.Extruded plastics are utilized throughout industrial and also business applications, with some of the most common being tubing, poles, and also specialized profiles. https://docs.google.com/spreadsheets/d/1IGIsVgnL3rL0oLJ3XeyNG44uV7itN_umy4KJgeVs6oo/edit#gid=0.

At Astro Plastics, our period in the sector and variety of top-end capacities enable us to supply on also one of the most complicated client demand. Our group of specialists functions carefully with you to tackle your custom-made plastic extrusion requires from concept to completion, making certain you receive the ideal product at the correct time.

Report this wiki page